Roundness measurement

on an electric motor

- Ø 8 mm

- Linearity: 0.25 %

- Zero maintenance LVDT

- Large number of cycles

TASK

If the shaft of an electric motor is not circular, this will produce vibrations at high speeds and hence increased wear. Irregular bearing surfaces may be one cause of a shaft running out of true. A bent shaft or a shaft without strict dimensional tolerances could also be the cause.

SPECIFIC REQUIREMENT

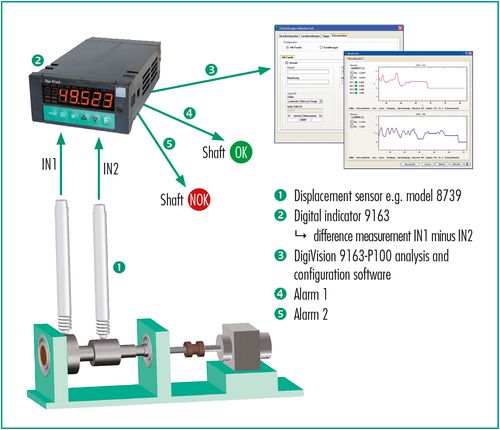

To guarantee the roundness of a shaft, two displacement sensors are used to measure the true running of the shaft. The displacement readings are checked to assess the roundness.

SOLUTION

As part of the quality assurance process, the shaft is tested for true running, bow and concentricity of the bearing surfaces. The test also includes measuring the diameter of the shaft bearings. In the test, the shaft is clamped in a holder and turned by a motor while being measured by two displacement sensors. The instrument measures the difference between the signals from these two sensors; this difference is only allowed to vary within a specified tolerance band. The 9163 digital indicator performs the difference calculation and assesses the results. As this process takes just a few seconds, both random sampling and 100% testing are possible. If the shaft does not lie within the tolerance band, the 9163 outputs an alarm signal. When used for testing random samples, the 9163 colour display provides additional support by changing from green to red if the shaft lies out of tolerance. The operator thus knows immediately whether the shaft is OK.

Go to product Digital Indicator 9163

Go to product 8739

Sectors

Downloads