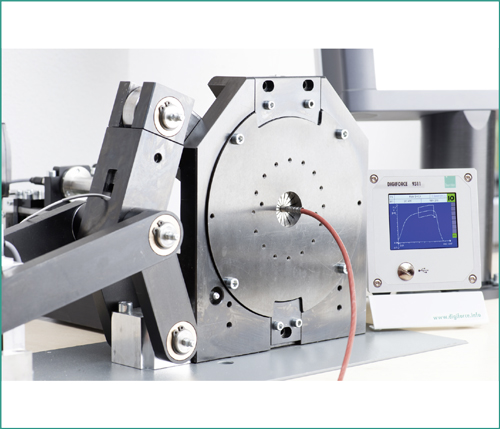

Monitoring the crimping process

of rotational symmetric parts

DIGIFORCE® 9311

- High sampling rate ensures high-speed recording of force signal

- 25 ms evaluation time

- Graphical evaluation elements used for monitoring

Compression load cell model 8526

- Compact design

- Stainless-steel construction

- Protection class IP64

TASK

A process that uses crimping and rolling machines to join (crimp) rotationally symmetric components and assemblies in a form-fit needs to be monitored. Depending on the machine design, 4 to 16 jaw segments compress the components symmetrically to produce a form-fit. In addition to 100% monitoring of the form-fit, the system must also identify a possible failure of one or more crimping jaw segments during the crimping process.

SPECIFIC REQUIREMENT

It is essential to ensure strain relief between sleeve and cable and/or that the joints are both liquid-tight and gas-tight. Since safety-critical components are often involved, these production processes must be fully documented with 100% process monitoring.

SOLUTION

To monitor the crimping process, the force applied by the jaw segments to the material deformation is analysed as a force/time curve. The 8526 compression load cell is located in the lever and measures the pressing force. The DIGIFORCE® 9311 analyzes the force/time curve synchronously with the crimping process. Recording the force signal at this rapid speed is possible thanks to the instrument's high sampling rate. The servo-drive delivers constant and reproducible movement (displacement) and therefore the force signal is recorded as a pure force/time curve. The measured X/Y curve is monitored using the envelope evaluation element.

Any failure, breakage or wear of a jaw segment produces a significant change in the force/time curve characteristic. The synchronous recording by the DIGIFORCE® 9311 can help to guarantee zero-fault monitoring thanks to immediate evaluation of the crimping process and the output of an OK/NOK signal.

<link https: www.youtube.com _blank external link in new>Watch the video "Monitoring the crimping process of rotational symmetric parts"

<link https: www.burster.com en measure-test-devices press-fit-jointing-torque-and-process-control p detail digiforcer-9311 _blank external link in new>Go to DIGIFORCE® 9311

<link https: www.burster.com en sensors force tension-and-compression-load-cells p detail _blank external link in new>Go to compression load cell model 8526

Go to product DIGIFORCE® 9311

Go to product 8526

Sectors

Downloads