Monitored press-fit processes

in the manufacture of battery trays

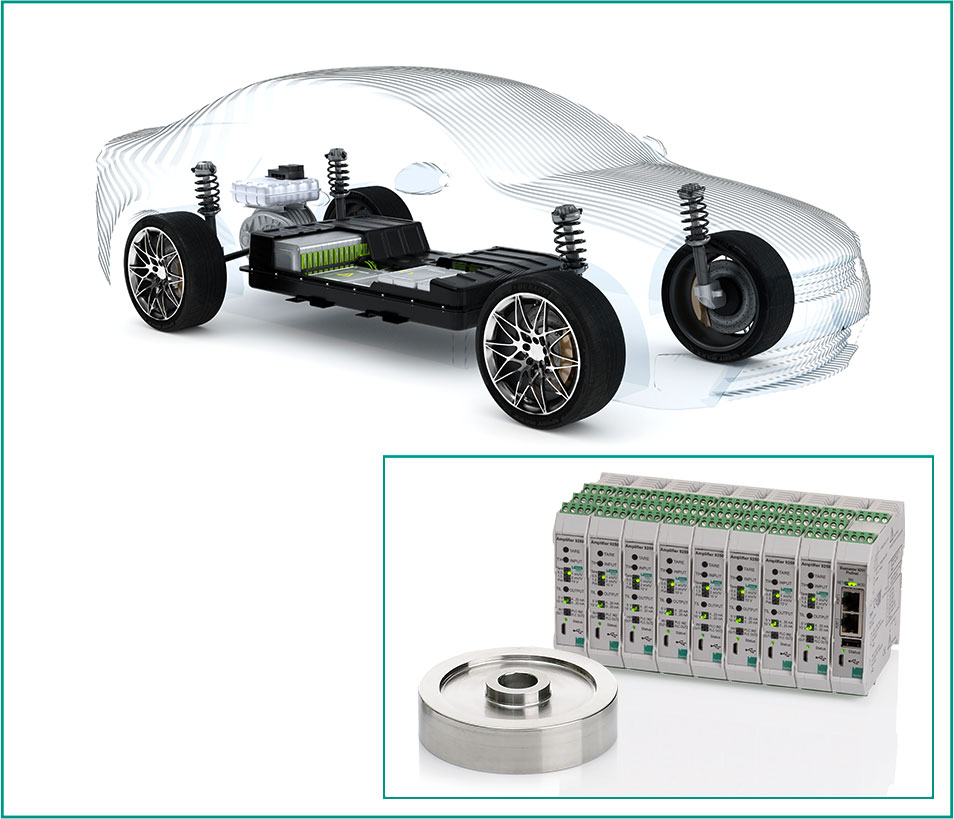

- Measurement of press-in forces during an assembly process

- Precise determination of forces with the ring force sensor type 8438

- Multi-channel force measurement with up to 8 channels with one fieldbus interface

- EtherCAT, PROFINET and EtherNet/IP capable measuring system

Description

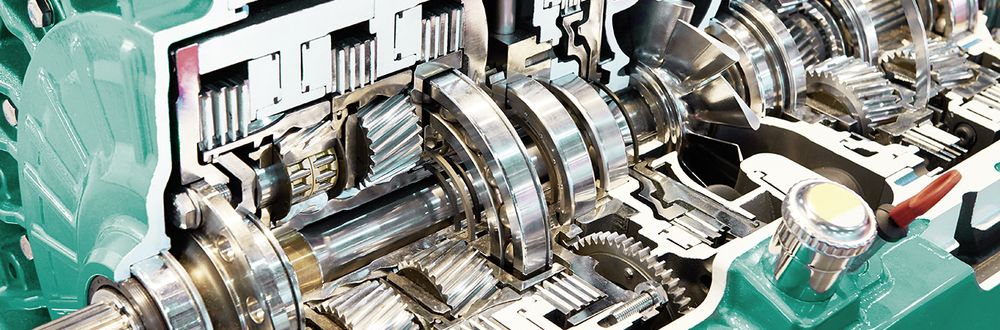

Battery trays must be carefully designed because they must protect the batteries, the heart of any electric vehicle, in the event of an accident. At the same time, it must be ensured that the battery trays can be opened if necessary, e.g. for maintenance of the battery cells. During the production of the battery trays, the bottom plate and the cover are connected by means of nuts. This connection must be secure, have guaranteed tightness, e.g. against dust, and be resistant to water pressure, as the battery cells are located in the space between them.

Special requirements

- High manufacturing quality of the battery trays

- Highest safety requirements

Solutions

Self-piercing nuts are used for the connection between the base plate and the cover. The press-fit process must have a 0-fault tolerance, which can be guaranteed with burster's process monitoring technology. The miniature ring force sensor 8438, which measures the press-in force, the potentiometric displacement sensor 8713, which determines the press-in displacement, and the combination of measuring amplifier 9250 and fieldbus controller 9251, which can be addressed with up to 8 measuring channels via a fieldbus interface and record and transmit the measured data, are used.

Go to product 9250

Go to product 9251

Go to product 8438

Go to product 8712, 8713

Sectors

Contactpersons